Please give a brief self-introduction

I am currently a senior engineer at the Tectonic Audio Labs where I joined in 2011.

The company offers loudspeaker drivers for the audio market.

Before that, I worked for several semiconductor companies as an application engineer.

Products included RF chipsets, microcontrollers, digital power electronics, and digital audio amplifiers.

My academic degrees (Ph.D., M.Phil., and B.Eng.) are all in electronic engineering.

I am a serious road-bike rider.😀

What tasks are you currently performing at your company?

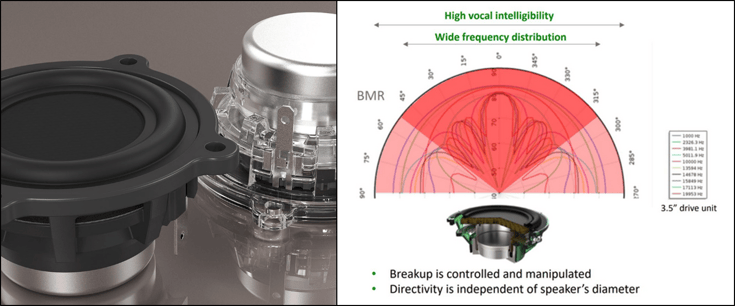

My main task is loudspeaker drivers design based on our patented technologies.

Design works cover electromagnetic, structural, acoustic and thermal.

We use FEA to optimize the electromagnetic circuit to deliver the desired driving force with the most economical magnet circuit.

A loudspeaker driver consists of moving and flexible parts which vibrate intentionally and unintentionally. Structural FEA helps to understand how parts are working together.

Based on the simulations, we can optimize parts’ geometry and select suitable material for each component.

In addition to structural analysis, we perform heat transfer studies.

It is important that the integrity of a driver is not compromised under maximum operating/environmental temperature.

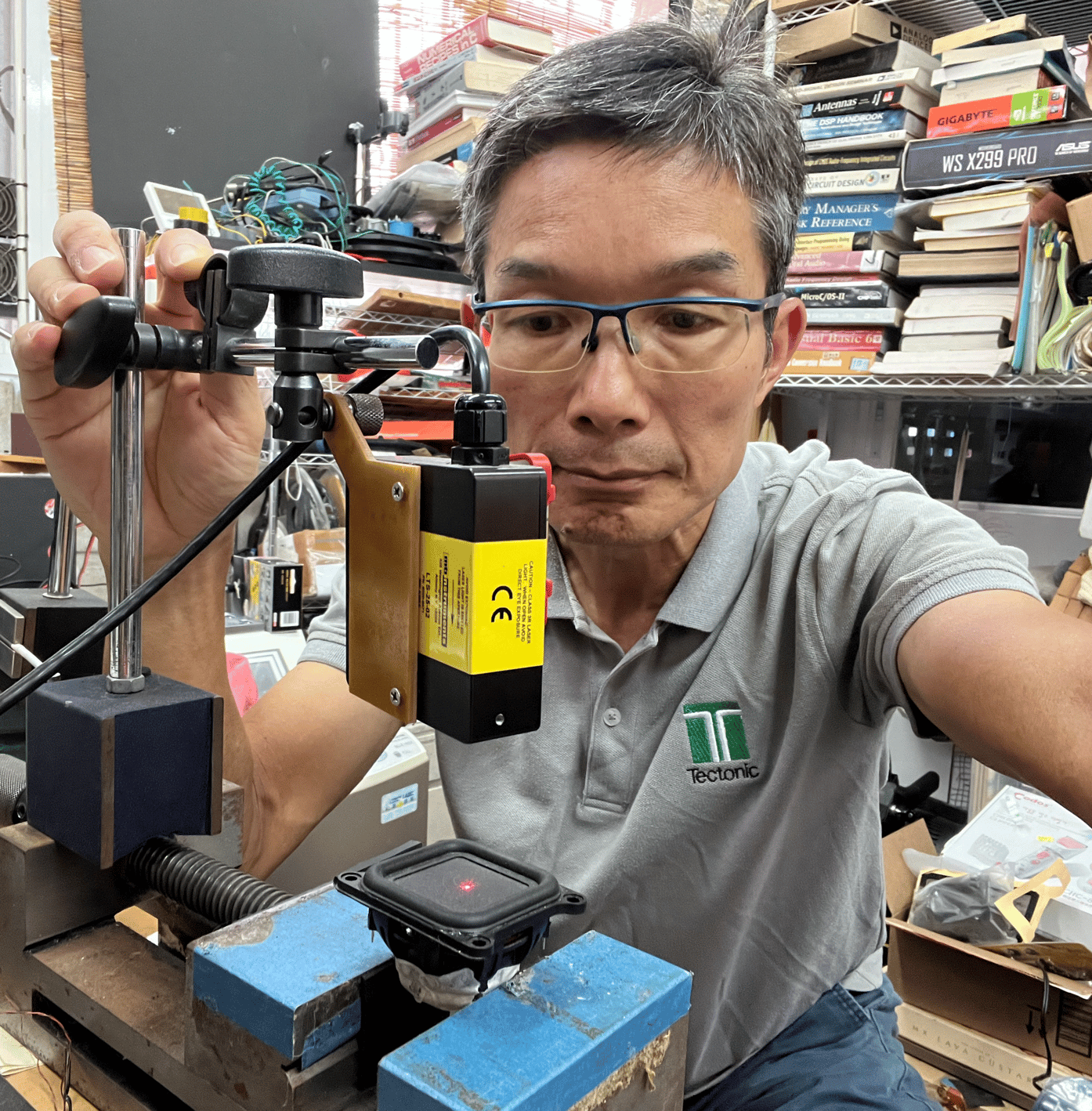

Measurement of prototypes and production units is also my routine task.

This includes mechanical vibration as well as acoustic measurements.

What was the rationale behind adopting midas NFX?

Cost to performance is a key consideration.💵💲

Compared to other FEA packages, midas NFX is a very affordable and powerful solution.👍

We get all the functionality for essentially one price, which is not the case for many other solutions.

The ease-of-use integrated GUI is an important advantage.

Structural and CFD are under the same user interface.👏

This is vital in learning a new tool and to deliver the first, quality output.

Among various CAE products, why did you choose midas NFX?

We need a tool for structural and CFD analysis.

Nonlinear (e.g. hyperelastic) material models is needed.

Fluid-solid heat transfer and two-way FSI are also beneficial to the overall development cycle.

With all these requirements, midas NFX stands out among other competing tools.

How is midas NFX being utilized in your company?

midas NFX is used for many structural analyses including modal, linear static and nonlinear static.

We compare its outputs to the outputs of another FEA package (structural-acoustic) in order to gain confidence of designs and sometimes for troubleshooting.

When we need hyper elastic modelling, midas NFX is the only choice.

Besides working together with the other FEA tool for structural analysis, midas NFX is the sole tool for CFD tasks.

We perform fluid-solid thermal analysis to estimate the temperature of a loudspeaker unit under maximum operating conditions.

Two-way FSI is helpful to accurately study the cooling effect from fluid flow induced by the diaphragm movement.

We can’t afford to have a driver melting or catching fire in the field.

What changes occurred after the adoption of midas NFX?

The onboard of midas NFX has helped us to predict operating temperatures during the design cycle instead of late till a prototype is available.

This saves us lots of time. We can either refine the design or select suitable material.

Eventually it shortens the time to market of a new product and avoid potential hidden risk.

If you were to recommend midas NFX to another company, why would you do so?

I think the simple pricing scheme is highly unique for midas NFX.

When a company considers its first FEA tool it commonly underestimates the requirements for their needs.

They may simply believe linear static is all they need.

To save cost, they invest in a tool with that option only.

This may fulfill their needs initially, but then realizing soon that they need more simulation capabilities to address various conditions of the products encountering in the field.

At the time, the company needs to invest much more in additional modules and maintenance cost is charged per module.

This is not the case for midas NFX. NFX is basically a one-stop-shop for one price.

To name a few, you got linear and non-linear structural analysis, linear and nonlinear material models, implicit/explicit transient, multi-body; CFD including two-way FSI, fluid-solid heat transfer, mixture and multiphase.

In one sentence, how would you describe midas NFX?

"midas NFX is awesome!"

This is in particular for SME (small, medium enterprise).

I know giant, multi-international firms are using it.

But for SME or start-ups with limited budget, midas NFX is hard to be beaten.

list view