What kind of work are you currently doing?

Nice to meet you My name is Sang-gi Yoon from the maintenance design team at Hyundai Steel . I am working on the analysis and design of large and small facilities in steel mills.

Since Hyundai Steelworks located in Dangjin is located near the sea, the facilities are easily corroded by salt from the sea. Also, due to the nature of the steel industry, maintenance workers are constantly exposed to strong heat and dust. For this reason, various issues such as cracks, vibration, and thermal deformation occur in steel facilities . It's happening right now , right now. 😲

There are about 46 factories in the steelworks , including large and small factories, and many of them are over 10 years old . Even if only 1 or 2 issues per plant occur, a total of over 100 analysis and design work is required . However, because the safety of many people and the quality of the product depend on it, you can never cut corners.

Hyundai steel work site

Source: Hyundai Steel homepage

There must be a lot of unexpected situations.

How are you coping with them?

Yes. Of course, there are problems that can be predicted, but problems that are difficult to predict occur every moment. During on-site operations, requests such as “equipment is broken”, “ thermal deformation has occurred ”, and “ building is bent ” are received from various directions . Although time-consuming and complex items can be handled efficiently through outsourcing, in most cases, we conduct structural reviews ourselves and deliver improvement designs and drawings. NFX is an important role in that process.

How was it when you actually tried it?

We've been using NFX for 8 years and it's really comfortable. First of all, it's nice that the user interface is in Korean, and it's easy to understand at a glance when adjusting numerical values, setting conditions, and checking the result. Technical support is also more than expected. If there is a blockage during use, we will go to you for training, or the technical support team will come to Dangjin directly. It's a job with a lot of unexpected situations, so I'm sorry for the day, but I'm grateful for the immediate help.

You said you have a lot of atypical problems. How are you using them?

Currently, 80% of our team structure review work is handled using NFX. As I said before, most of them cover everything from predictable problems to atypical unexpected situations . I think this is because NFX basically stably supports linear static analysis and non-linear analysis . In the case of NFX, since the analysis speed can be changed by using multi-core , it seems that the analysis can be performed faster if the computer performance supports it .

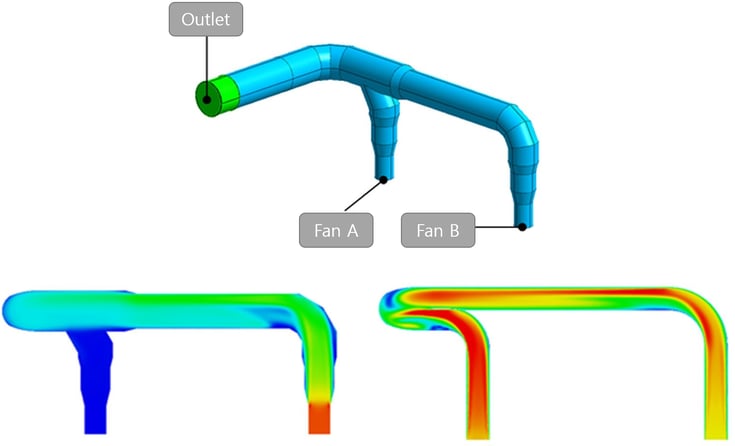

Duct design using NFX – air inflow improvement/ (left-before improvement, right-after improvement)

Source: Provided by Hyundai Steel

I think you put a lot of thought into reviewing the program.

Why did you choose NFX as your first program?

I've met a lot of people who work at Midas IT , but I can feel their sincerity . I think it's because you talked without lies and without embellishment . Even if there are weak points, they tell me about them without hiding them .

I've known him for 8 years, but he's very honest and caring. I think the trust I felt from the salesperson became my trust in the company. I thought, “I can trust and use this company’s product.”

MIDASIT Manager Sung-chan Jung(left) and Hyundai steel Sang-gi Yoon(right)

Changes after introduction?

The steelworks work on facility improvement once or twice a year through the Daeboso. In the process, NFX was of course used, and the efficiency in my work improved. Through the NFX upgrade, mesh creation has become more convenient, and editing work has become easier, so work time has been shortened. Density has also improved considerably. Compared to before the introduction, I feel that the work speed has improved by 2-3 times.

Who is right for NFX?

"If you use NFX for steel and structure design and manufacturing companies, you will be able to bring product stability and reliability."

Even for small and medium-sized businesses, especially those that supply to large corporations, I believe that a basic safety review is necessary. This is because a clear difference can be seen from the drawing between the company that did the structural review and the company that did not. Therefore, among small and medium-sized companies, steel and structure companies and manufacturing companies will be able to bring product stability and reliability if they use NFX.