Q. Please briefly introduce yourself.

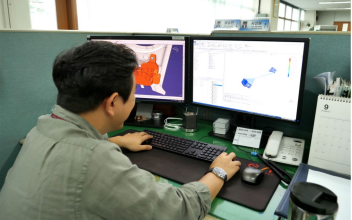

Hello. I am Lee Kyung-gyu, manager of the KIA Molding Design Team.

My team is responsible for designing the body parts production tools,

and I am responsible for strength analysis in the broad area of mold design.

Q. Please explain the molding design.

In the past, body parts were mainly produced using presses and molds, but recently, body parts are being produced using various production technologies, not limited to presses. In line with this trend, our team was also in charge of various production technologies, not just press molds, and the expression 'form design' came out.

Q. What was the background of introducing MeshFree?

For every new car launched, dozens of molds are designed just for that car. In this design process, there are often areas where strength problems are expected for each mold, but our team, which is not a professional analysis team, is realistically short of manpower and schedule for strength analysis using existing analysis tools every time. To solve this inconvenience, MeshFree was introduced.

Q. Why did you choose MeshFree among the various CAE products?

I think the biggest advantage of MeshFree is that there is no preprocessing process of existing professional analysis tools. The CAE product we wanted was 'quick, simple and accurate'. In this regard, MeshFree, which has no preprocessing, was introduced as it best suited what our team wanted.

MeshFree without cumbersome pre-processing!

Fast, simple and accurate!

Q. How is MeshFree being used in KIA?

Taking a press mold as an example, when forming a panel, the press sometimes presses the mold with thousands of tons of force. At this time, the mold locally takes tens of tons of force. No matter how hard a metal material is used, structural strength is not secured, so if breakage/deformation occurs, production will be greatly hindered. To prevent this, strength verification is performed from the design stage, and MeshFree is used at this time.

Q. What has changed since the introduction of MeshFree?

When damage/deformation is expected or actually occurs In the past, it was simply reinforcing the relevant part, but now we are reviewing how much reinforcement will be done by looking at the analysis results. In case of lack of experience, there are many cases where it is difficult to predict which parts are weak and how much to reinforce.

simply get the result

can design quickly

It helps me a lot in my work!

Q. What if you would recommend MeshFree to other companies?

Most of the design teams, like our team, will have a desire to do a strength check without any pressure while designing. However, I think that there are many cases where analysis is not possible due to the high entry barrier of existing analysis tools. In the case of MeshFree, I think that it will be able to satisfy the desire for analysis by reducing preprocessing man-hours and obtaining analysis results with a simple UI even if you are not an expert in analysis.

Q. How would you describe MeshFree in one word?

MeshFree is 'Short-cut'!

This is because it is a shortcut that can be simulated immediately beyond the cumbersome preprocessing step.

MeshFree is a 'pain reliever'!

This is because it frees you from the painful MESH work.

MeshFree is a 'booster'!

This is because it increases the work speed as if you had a booster.